Anodizing & Hard Anodizing

Aluminium surface is always covered by a natural oxide layer ( alumina). This layer is subject to deterioration because of its fragility caused both by the low thickness and its non-homogenous nature.

Aluminium surface is always covered by a natural oxide layer ( alumina). This layer is subject to deterioration because of its fragility caused both by the low thickness and its non-homogenous nature.

The anodizing process ( eloxation) which we perform, allow us to control the thickness of this oxide layer obtaining a homogenous and resistant layer.

Using special coloring agents it is possible to color the anodized layer. The coloring of the deposited layer is an additional operation and optional. The only way to remove the color of the piece is the destruction of the anodized layer.

The anodizing process ( eloxation) is finalized by the pore clogging by the hydration of the oxide layer formed. Once the pores have been clogged, a better resistance to corrosion is obtained.

The layer of deposited aluminium oxide has also electric properties. The presence of the anodized layer on the surface of a piece made of aluminium prevents the electric current flow.

The porosity of the anodized surfaces allow a very good adhering to the electrostatic field painting or when two surfaces are stuck together.

The aluminium pieces have a crystalline structure depending on the thermal treatment of the pieces or the raw material they were manufactured of. During the anodizing treatment , further to the action of the aggressive solutions of the baths , the crystalline structure could be sometimes, made evident.

The processing of the aluminium piece surfaces may hide some material defects. The irregularities of the aluminium surfaces corrected by grinding can occur again after the piece degreasing and passivating ( the micro – defects of the surface are filled during the grinding and the surface looks smooth, but when the surface is cleaned by degreasing and passivating operations, removing the dust from these small holes , the micro-defect is again made evident).

To be able to perform the anodizing ( eloxation) of a piece it is essential that electric contact points exist on the piece surface. At these contact points, no oxide layer is formed and so it is possible to notice white traces. The piece contact zone will be selected so that to maintain the esthetical appearance of the pieces.

In the zone of the welding cords, the pieces are submitted to thermal treatment, the metal micro-structure being affected and thus there will occur obvious differences between the aluminium piece basic metal and the welded zone.. The welded sector shows a much darker color compared to the rest of the piece. Moreover, the welded sector can show an uneven appearance.

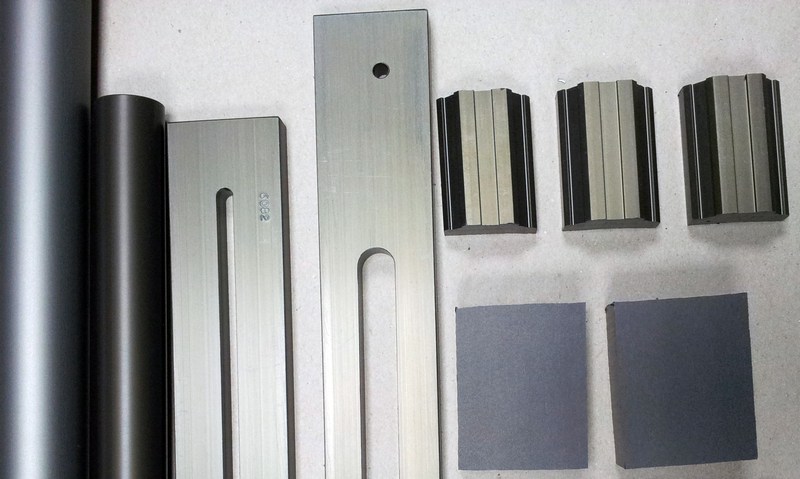

Hard Anodizing

The hard anodizing observes the same principles of formation as the decorative and protection anodizing. The difference consists in the fact that the hard anodizing is realized at low temperature and high intensity of the electric current. The pores of the layer hardly anodized are smaller than those ones of the classical anodizing.

The hard anodizing installation from ANOROM allows the obtaining of a layer with the thickness up to 100 μm. The layer hardness varies depending on the alloy between 300 and 800 HV at a layer thickness of 50 μm.

The alloys recommended for anodizing are from the series 5000, 6000 and 7000. The alloys from the series 2000 present risks of the part burning-out, the layer thickness and its hardness being more lower than for the other series. The alloys 2011, 2007 and 2030 are not suitable for the hard anodizing treatment.

The main properties of the hardly anodized layer: electric insulator, thermal insulator, attrition-resistant, scratch-proof.

Maintenance of the anodized pieces (eloxation).

The periodical maintenance of the anodized surfaces is essential for removing the dirt or different depositions. By means of a good maintenance will be avoided the piece spots which could show the partial or complete destruction of the anodized layer. The pH of the solutions must range between 6 and 9 , but if outside this range the oxide layer will be attacked.

Behavior of aluminium alloys at sulfuric anodizing ( eloxation )

All the aluminium alloys can be anodized but their behavior is different during the treatment.

Here is a brief review of the different behaviors of the alloys to anodizing process:

The alloys of the 1000 series ( pure aluminium ). Good response to the anodizing treatment, The more pure is the aluminium the more transparent is the anodized layer.

The alloys of 2000 series ( copper alloys) . Copper of this alloy dissolves during the treatment, obtaining a not attractive (milky appearance) surface . The coloring of this alloy is also unaesthetic because of the copper presence which prevents the uniform deposition of the aluminium oxide layer. The unevenness of the deposited layer results also in the mitigation of the surface hardness and implicitly of the resistance to abrasion.

The alloys of 3000 series ( manganese alloys). At concentrations higher than 1% Mn the anodized layer has a less pleasant grey – bluish color and thus, the piece surface appearance is unaesthetic.

The alloys of 5000 series ( magnesium alloys). Good behavior at anodizing. Up to a concentration of 3% Mg the anodized layer is colorless. The higher than 3 % is the magnesium concentration , the anodized layer color become more grayish . Sometimes, there can be noticed light yellow tones if the alloy contains traces of manganese or chromium.

The alloys of 6000 series ( magnesium and silica alloys). Their behavior at anodizing and coloring is very good and the appearance of the anodized layer is very homogenous. The pieces made of this alloy can be enameled to obtain an unpolished appearance of the surface. When the thickness of the anodized layer is higher than 30µm, the piece surface gets a dark grey color.

Alloys of 7000 series (zinc alloys). The thicker the anodized layer is, it is easier to better notice yellow- greenish appearance of the anodized piece surface. Some of the alloys of the 7000 series may contain copper, too ( for instance alloy 7075) and behaves like a 2000 alloy at anodizing, and the anodized surface is unaesthetic. There are alloys of 7000 series with low copper content (for instance 7020 alloy ) which behavior is good at anodizing obtaining a uniform appearance of the anodized surface.